What You Need to Know About PERC Solar Cells

What You Need to Know About PERC Solar Cells 2025

For decades, conventional silicon photovoltaic (PV) cells have dominated the solar industry. However, as this technology matures and

approaches efficiency limits, researchers and manufacturers have turned to a promising alternative — the Passivated Emitter and

Rear Contact, or **PERC solar cell**. In this article, we’ll explore the core advantages of PERC technology, how it works, the

manufacturing process, and why it can be a game-changer for selling solar systems.

How Standard Solar Cells Work

Traditional solar cells are built with two layers of silicon: the “n-type” layer with negative charge carriers, and the “p-type” layer

with positive charge carriers. When sunlight strikes the cell, photons knock electrons loose from the n-type layer, which are then captured

by the p-type layer. This creates an electric field, generating clean, renewable energy for homes and businesses.

While this design is reliable, standard PV cells face several sources of efficiency loss:

- Some sunlight is lost due to surface reflection or shadowing from wires.

- Heat buildup reduces performance, especially from light absorbed by the cell’s back surface.

- Scattered light can cause electrons to move out of alignment.

- Electron recombination at the front and back layers reduces overall power output.

Front passivation layers help minimize recombination and reflection, while placing wiring on the rear side or adding a back surface field

layer can improve performance. Still, standard PV panels usually max out at around 20% real-world efficiency due to heat losses

and back-side recombination.

What Are PERC Solar Panels and How Do They Work?

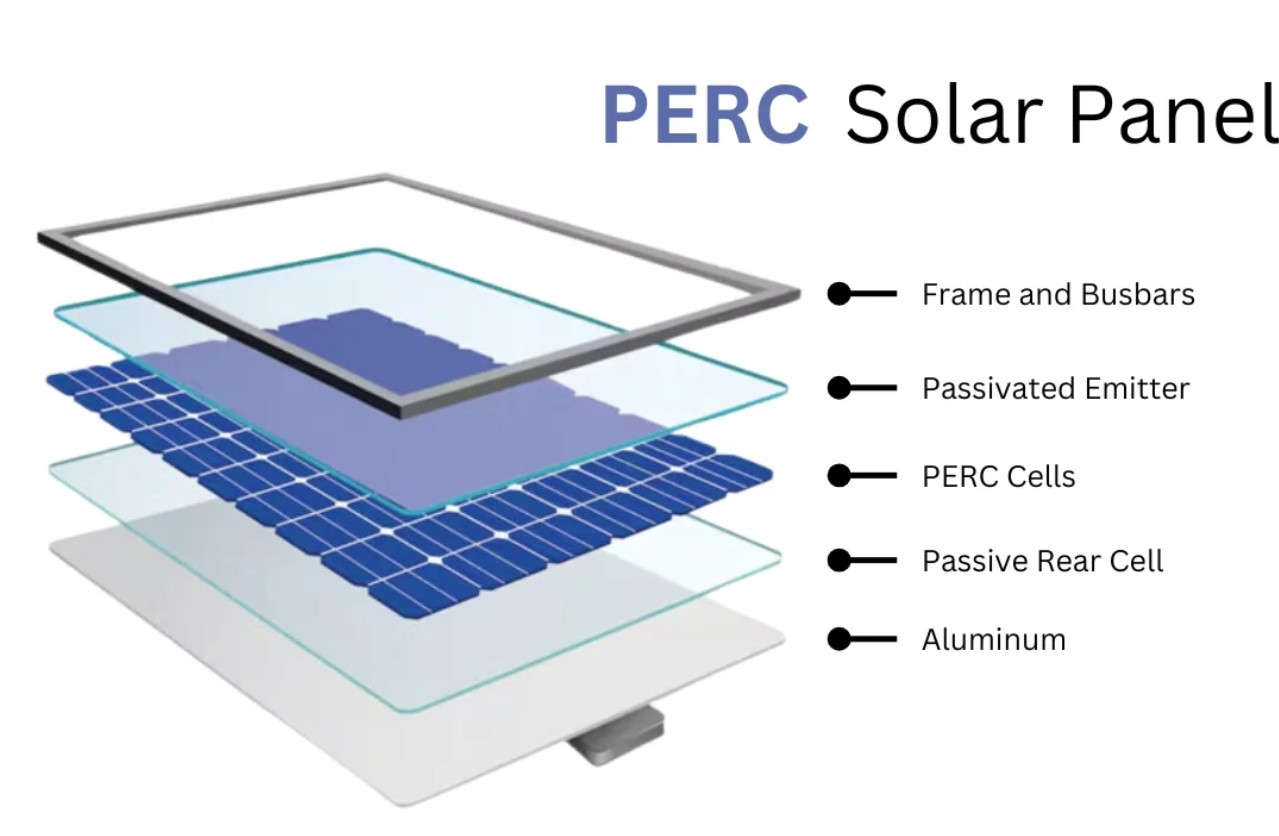

PERC technology, first introduced in 1989, modifies standard **silicon solar cells** by adding a special reflective layer to the back surface.

This layer sends unused light back through the cell for a second chance at energy conversion. It also reduces rear recombination and

minimizes heat buildup from long-wavelength light.

Although early commercial versions suffered from light-induced degradation, advancements in materials and processes have made

PERC panels far more efficient — up to 12% higher than traditional PV panels. This means fewer panels are needed to produce the same

amount of energy, saving on racking, wiring, and microinverter costs.

For example, if a project requires 40 standard panels but only 38 **PERC solar panels** to meet annual production goals, installers

can reduce installation time and material use, lowering overall costs.

PERC Module Production

Manufacturing PERC modules is similar to producing conventional silicon solar panels, allowing manufacturers to adapt existing

production lines with minimal changes. The main differences are the additional passivation and rear reflective layers, which slightly

increase production costs.

However, these extra costs are often offset by higher efficiency, which delivers greater lifetime electricity savings and carbon reductions

for end users. As economies of scale increase, both efficiency and cost-effectiveness are expected to improve.

Types of PERC Solar Modules

Mono PERC Cells

**Monocrystalline solar module** technology uses single-crystal silicon wafers, offering the highest efficiency among panel types.

Adding a PERC layer boosts their performance further, making them the preferred choice for modern solar installations.

Poly PERC Cells

Polycrystalline PERC cells are made from multiple silicon fragments. While they cost less to produce than monocrystalline cells, they are

less efficient. Adding PERC technology can narrow the performance gap without significantly impacting production costs, though they

remain less powerful than **solar cell monocrystalline** options.

Growth in PERC Cell Production

Demand for PERC modules surged in the late 2010s and continues to grow steadily. In 2021, the global PERC market was valued at

approximately $150 billion, with forecasts predicting it will reach $290 billion by 2030.

While PERC currently leads the solar market, some experts believe it could eventually give way to N-type solar cells, which offer even

higher conversion efficiencies.

Pros and Cons of PERC Solar Panels

Pros of PERC Solar Panels

- Higher efficiency compared to traditional PV panels

- Better performance in low-light and high-temperature conditions

- More affordable than advanced N-type cells

Cons of PERC Solar Panels

- Slightly more expensive than conventional silicon panels

- Lower efficiency than N-type technology

- More sensitive to temperature than N-type panels

How Offering PERC Solar Panels Can Increase Solar Sales

The key selling point of PERC panels is efficiency. Space-limited properties benefit from maximum energy generation per panel, and they

perform well even under partial shade or high heat. That means better returns for customers with small or less-than-ideal installation sites.

Even where space is not an issue, PERC technology helps reduce installation time and materials by requiring fewer modules for the

same output.

Side-by-Side Cost Comparison: Traditional vs. PERC Solar Panels

Many customers focus on upfront cost, but showing long-term savings can close the deal. With better efficiency and more energy

generated over the panel’s lifetime, PERC panels can deliver greater value despite a higher initial investment.

Next Steps

Educated buyers are confident buyers. When selling PERC technology, give customers detailed, easy-to-understand resources. Consider

providing a Solar Sales Follow-Up Kit that explains the basics of solar and highlights the long-term benefits of choosing PERC — helping

them make a decision that’s good for both their wallet and the environment.